Buildings can no longer be operated with a singular focus on separate systems like HVAC, electrical, lighting, tenant usage patterns, and the building envelope – NOT if it is to function as a high performing building. And, because buildings do not operate in a static state, they must be constantly managed to keep pace with an ever- changing facility environment. We seek to CONVERGE people, technology, and systems to come up with the most creative and effective solutions for energy optimization. By employing a combination of preventive maintenance with predictive and prescriptive measures we can find ways to improve a buildings net operating income, increase the ROI on energy conservation measures, and ultimately improve the value of the building asset.

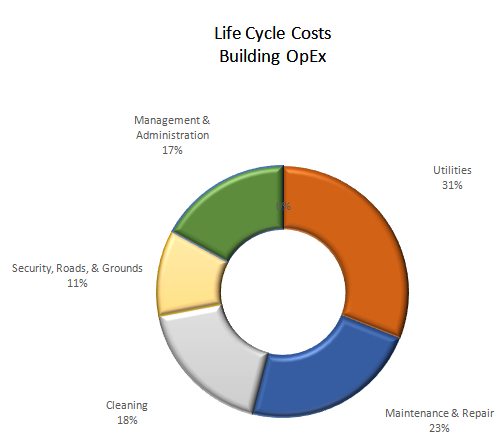

According to the Building Owners & Management Association (BOMA), in the life cycle of a building, approximately 31% of the operating expense will be attributed to the cost of utilities while another 23% to ongoing maintenance & repair.

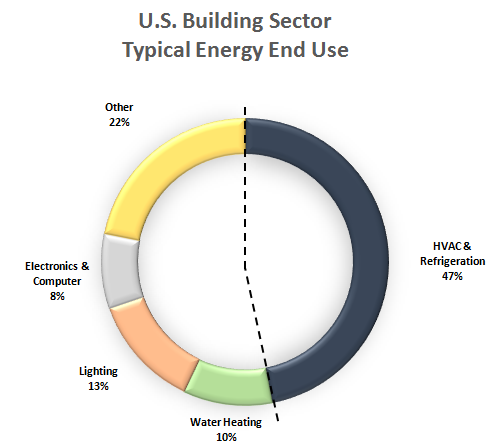

Further, when you consider that according to the Energy Information Administration, 47% of a building’s typical energy use is attributable to the HVAC systems, it becomes apparent that traditional methods of operating and maintenance (O&M) are not best suited for today’s building environment.

Traditional building O&M does not take into account effects on the cost of building administration and utilities. By changing the perspective, we can identify solutions that can positively affect almost 54% of a building’s activities. Gains of 5% – 20% on utility bills can be easily achieved without requiring major capital investments, and these dollars are immediately “released” to be applied to more critical needs or perhaps higher earning building investments.

Harvesting a significant return on energy initiatives is not solely the domain of large buildings. According to the CBESC, over 99% of the buildings in the commercial market are under 200,000 SF, those buildings are using 75% of the total energy consumed by all commercial buildings. Whether your facility is large or small, we can help you implement energy optimization measures that are both feasible and cost effective.

At Converge Systems Company we focus on getting the most out of the O&M portion of the building’s life cycle. The cost of designing and constructing a new HVAC system is only about 5%-10% of the total building life cycle cost while the cost of operation which represents about 60%-85%! We believe that better data allows for better and more informed decisions.

ENERGY BENCHMARKING

Operators of high performing buildings are twice as likely to integrate key operational metrics with financial decision making. Introducing energy consumption data into the decision matrix opens more options for you to improve your bottom line. By providing an Energy Star benchmark, we can rate your facility’s energy performance against a national database of thousands of similar-use buildings.

The Energy Star program was developed jointly by the U.S. Environmental Protection Agency and the Department of Energy, and the benchmark is provided as a numerical rating between 1 – 100. The rating tells you where you stand in comparison to your peers. It provides a data driven framework around which you can make objective, informed decisions as well as developing smarter goals for your facility’s energy optimization.

ENERGY AUDITS

While energy benchmarking is the first step to gaging your overall energy consumption level, an energy audit of your facility will provide a more detailed analysis that helps you identify specific measures that would result in a reduction in energy spend. Our energy audits are conducted based on standards set by ASHRAE for Level 1, Level 2, and Level 3. Energy audits can be used for a wide range of reasons. You may be interested in developing specific energy conservation measures or you may be interested in developing a master plan / objective for your facility. The three levels of audits can be custom tailored to fit what need.

CONTINUOUS COMMISSIONING & RETRO-COMMISSIONING

All buildings suffer performance degradation due to regular wear & tear, performance “drift”, improper startups & commissioning, inadequate designs, or incorrect sequences of operation – just to name a few reasons. Whether your facility is new or old, all buildings need to be regularly “tuned” in order to assure that current load requirements are being met efficiently. By continually monitoring performance, you will prevent losses that normally go undetected for long periods of time and potentially cost you thousands of dollars. Consistency in a process is very important if you want to get y our energy consumption under control, and a constant commissioning effort will guarantee your system will be operating at peak condition all around the clock.

UTILITY BILL ANALYSIS

Ensuring that your facility is under the most appropriate rate structure while verifying that billed charges and tax rates are correctly assessed is a low cost measure that brings visibility to issues such as changes in annual expenditures, tenant occupancy & usage patterns, or KW demand. It’s an opportunity to recoup money that is just being wasted.

FAULT DETECTION & PRESCRIPTIVE ANALYTICS

Using proprietary energy management software allows for immediate detection of anomalies in system performance. These faults are detected in real time and then presented and prioritized in a list that indicates the financial impact to your organization. Then it is up to you to decide on what to take action. Catching these issues without these cutting edge technologies was not possible just a few short years ago, but now the technologies are well developed and cost effective.

CENTRAL ENERGY PLANT OPTIMIZATION

Most chill water plants fail to operate at their intended design despite investments in high efficiency components such as chillers, variable frequency drives, pumps, and cooling towers. In fact, they may be draining 30%-40% more energy than is required to provide the cooling you need. The efficient operation of a chill water plant is dependent on many factors outside of the full load efficiency of any single component, and today’s standard building management systems are not ideally suited for providing a continuous platform to evaluate the real time operating condition.

Using proprietary sensors, flow measurement devices, and KW metering equipment we can provide a cloud based system to keep your plant running at peak efficiency. Not only does the system provide real time analytics and fault detection – it will also provide the monetary loss by item that you are experiencing if the defect goes unaddressed. Best of all – these solutions are provided as a monthly service and require no up-front capital investment.

BUILDING MANAGEMENT SYSTEMS

DDC Control systems are no different than mechanical equipment in that they require maintenance and service to keep properly operating. Controls systems may “drift” from their original sequences of operations and settings. Sensors and devices may malfunction and provide erroneous data that keeps systems operating longer than they should.

Converge has the expertise to work with all systems in order to support industry standards such as BACnet and LONWorks. We have expertise in many leading control systems such as Johnson Controls Metasys, Facility Explorer, Dis-Tech, Andover, and we can integrate systems using Niagra framework. Whether it is a new system, an upgrade, an expansion, or a retrofit of an old system, Converge Systems Company can provide the know how to make your controls project a successful one.

MARKET SECTORS

* Industrial

* Commercial Office

* Hospitality

* Educational

* Correctional Facilities

* Health Care

* Data Centers

* Entertainment